Understanding Your Kenworth's Tractor Protection Valve

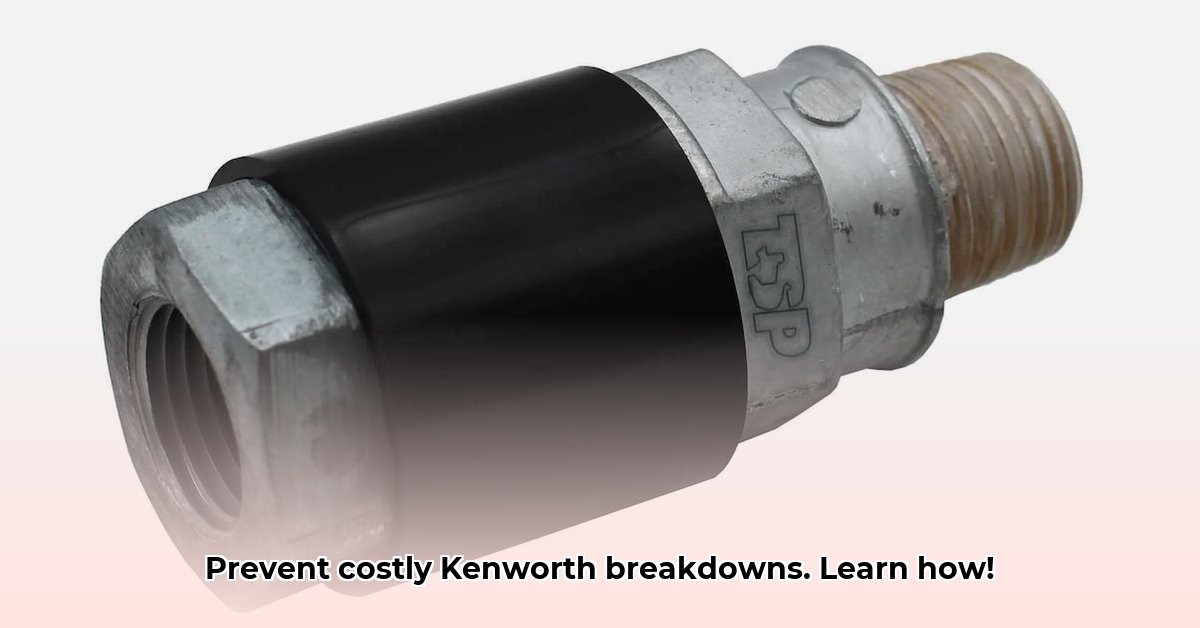

Your Kenworth's tractor protection valve is a critical safety component, silently safeguarding your truck's hydraulic and pneumatic systems. Think of it as a pressure safety valve, preventing dangerous pressure buildups and leaks that could severely damage your transmission, brakes, and other essential components. Neglecting this unsung hero can lead to costly repairs and potential safety hazards. This guide will empower you to understand its function, perform routine maintenance, and troubleshoot common issues.

Giving Your Valve a Once-Over: A Quick Visual Inspection

Before diving into more involved maintenance, a quick visual inspection is crucial – a preventative health checkup for your valve. Look for:

- Leaks: Any fluid dripping or seeping around the valve, connecting pipes, or fittings? Even minor leaks indicate a potential problem.

- Corrosion: Rust or corrosion, particularly in weather-exposed areas? Corrosion weakens the valve's integrity.

- Damage: Bumps, cracks, or dents on the valve or its connections? Damage compromises its structural strength.

- Secure Connections: Are all fittings and pipes firmly connected? Loose connections are prime leak candidates.

Preventative Maintenance: A Proactive Approach

Regular maintenance is significantly cheaper than emergency repairs; consider it preventative medicine for your truck. Here's a straightforward plan:

- Cleaning: Gently clean the valve and surrounding area with an appropriate cleaner, avoiding damage to seals. A soft brush and mild detergent usually suffice.

- Pressure Check: Consult your Kenworth's owner's manual for the correct pressure settings. Use a pressure gauge to ensure pressure is within the specified range. Deviations require further investigation.

- Seal Check: Carefully inspect all seals and O-rings for wear, cracking, or damage. Replace any compromised seals to prevent leaks. These small components are critical for system integrity.

- Lubrication (When Applicable): If your valve has moving parts, refer to your manual for proper lubrication guidelines. A light coat of approved lubricant ensures smooth operation and reduces wear.

- Environmental Cleanliness: Maintain a clean environment around the valve to prevent dirt and debris from entering and causing issues. This simple step significantly reduces the risk of contamination.

Troubleshooting Common Issues

Despite preventative measures, problems can arise. Here are some common issues and potential causes:

- No Pressure: First, check the air supply and electrical connections to the valve. Persistent issues suggest an internal valve problem needing professional attention. This could indicate a more serious mechanical failure.

- Intermittent Operation: Investigate loose connections or damaged seals. A faulty pressure relief valve might also be the culprit. Intermittent function points to a partial blockage or a failing component.

- Excessive Leakage: Worn seals or O-rings are usually the cause. Replacement is the typical solution. Excessive leakage significantly reduces system pressure and can lead to safety hazards.

When Professional Help is Necessary

If you encounter any serious issues or are uncomfortable performing maintenance, contact a qualified Kenworth mechanic. Their expertise ensures proper diagnosis and repair, maintaining your truck's safety and reliability. A well-maintained tractor protection valve is crucial for both safe operation and efficient freight delivery. Don't gamble with safety.

Weighing the Pros and Cons of Preventative Maintenance

| Pros | Cons |

|---|---|

| Significantly extends valve lifespan | Requires time and effort |

| Prevents costly repairs | May require specialized tools |

| Enhances safety and reliability | Risk of mistakes if done incorrectly |

| Improves uptime; reduces downtime | Potential upfront cost for parts/materials |

Important Note: This guide provides general information. Always refer to your Kenworth's official service manual for model-specific instructions and safety recommendations. Prioritize safety and proper procedure above all else.